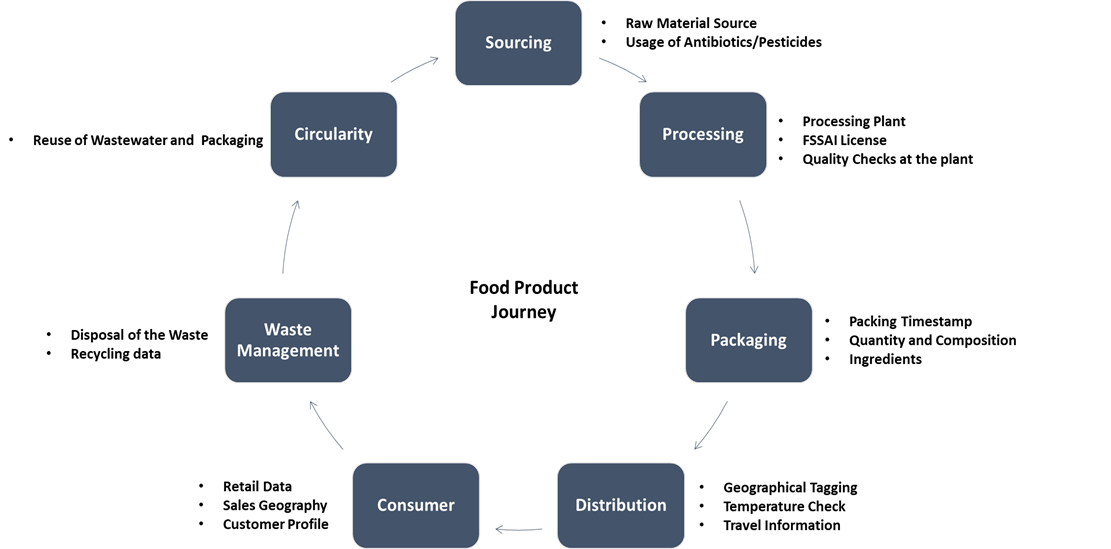

Imagine that by scanning the unique code on each food product, you can access information including the product batch number, the production and expiry dates, the region that the raw material was sourced from and a certificate of inspection. Being able to determine where food has come from and that it is safe to consume is important to an end consumer. There is also a strong link between authenticity and produce origins, and food safety and quality.

Traceability is a paradigm shift in modern food supply chain. And the technology is already available to trace each raw material that goes into a product and follow how a product is used and where it is discarded. The rise of the internet of things (IoT) will also help in tracking of food products in supply chain. Sensors are coming onto the market that track not only the location of goods, but also the orientation of crates (containing food packets) and factors such as temperature and humidity. Traceability enables companies to meet and balance a broader set of business objectives, including efficiency, resilience, responsiveness, and sustainability.

Traceability gives companies the ability to follow products and goods as they move along the value chain and to extract information about the origin of inputs, supplier sourcing practices, and manufacturing processes. With that data in hand, companies can make predictions, run production scenarios, and streamline operations. Companies can also identify strategic supply chain opportunities, innovate faster, minimize the impact of internal and external disruptions, and certify sustainable processes and products.

Food Sector – Supply Chain in India

The food and agriculture sector are the single largest employer in India. India witnesses nearly 5-15 % (About $ 13 Billion in value) wastage in fruits and vegetables annually, due to lack of modern harvesting technologies and cold chain infrastructure. And a rising population, expected to reach almost 1.6 billion by 2030, exacerbates our already strained food systems. Hence it is very important to focus on the supply chain to figure out the inefficiencies and weed them out so that our food supply chain is able to withstand the growing demand.

People ask about connection between sustainability and traceability, and it is often misunderstood. Traceability is the ability to follow materials from the beginning of the supply chain to the customer who purchases a product. With this data and information, traceability plays two roles that support sustainability. It provides visibility on inputs and processes across the value chain, and it provides the source information for its origins and sustainability certifications. It could potentially facilitate comprehensive tracking of the environmental, economic, health and social consequences of different agricultural production processes, even making it possible to calculate the true cost of food to consumer, which will help meet consumer demand for transparency. Consumers might favour a locally grown produce than a produce which has travelled a long distance to the retail shelf. In addition, producers, including small-scale producers, also look to harness potential efficiencies brought about through traceability-enabled transparency, such as associated cost savings and new value sources. Traceability could also improve farmers/producer revenue, market access and opportunities for affordable access to capital.

Circularity – A special mention

It is a recent industry phenomenon which can be broadly understood as reuse, restoration, and recycling of Industrial waste. However, it is one important topic that’s being discussed by industries globally. I was talking to a global food processing company which is going to set up a plant in India and they were concerned about wastewater from their plant and were investing a huge amount in its water recycling plant looking at the future trends in waste management. Similarly, an Indian FMCG conglomerate was concerned about the plastic waste generated from their packaging waste. These companies are looking at sustainable waste management solutions. Capturing the economic and material value of industrial waste, rather than allowing it to enter the environment, requires a system wide approach that leverages opportunities across the food supply chain. Effective solutions that can track the waste and its proper management will provide a broad set of investment opportunities across the manufacturing sector. We at Invest India have a dedicated team (Waste to Wealth) that helps companies find innovative solutions to waste management at their manufacturing plants.

Initiatives of Government of India

Traceability provides a significant opportunity to create value for consumers, producers, and supply-chain operators. One key opportunity is the potential to identify and address loss points in the supply chain, which is a particular challenge for India, and it holds a distinct promise in helping drive food-systems transformation. It has the potential to strengthen inclusivity and empower small-scale producers with improved market visibility and access to new services and resources. However, to ensure that its potential impact is maximized, the traceability agenda must focus on ways to introduce inclusive scaling, particularly in relation to medium and small-scale industries.

With this in mind, Ministry of Food Processing Industries has launched Operation Greens with the following objectives.

- Enhancing value realisation of farmers by targeted interventions to strengthen production clusters and their Farmer Producer Organisations and linking/connecting them with the market.

- Price stabilisation for producers and consumers by proper production planning in the clusters.

- Reduction in post-harvest losses by creation of farm gate infrastructure, development of suitable agro-logistics, creation of appropriate storage capacity linking consumption centres.

- Increase in food processing capacities and value addition in value chain with firm linkages with production clusters.

- Setting up of a market intelligence network to collect and collate real time data on demand and supply and price of crops.

The scheme will have two-pronged strategy of price stabilisation measures (for short term) and integrated value chain development projects (for long term).

Challenges in implementing Food Traceability

Full-scale traceability would be difficult for a food value chain player to achieve alone, as barriers to adoption are significant on a large scale (the financing of capital expenditures and establishment of consistent standards, usage of technology). Collaborations will likely come in one of three forms: horizontal (the largest global retailers and food companies work together to align on standards and put pressure on the rest of the supply chain to comply), vertical (one retailer collaborates with their full supply chain to align on standards) or multi-stakeholder (companies collaborate with players from throughout the entire value chain with support from government and consumers). Multi-stakeholder collaboration is preferable to the other two forms because it helps set consistent standards, taking into consideration the needs and perspectives of the full supply chain.

Traceability in food value chains, coupled with multi-stakeholder collaboration, has the potential to fundamentally improve food supply chains. To achieve its full potential, stakeholders will need to come together to enable emerging technologies and to install a broad system and standards in traceability. Without multi-stakeholder collaboration, the impact of traceability could be limited. Traceability requirements could become operationally and financially burdensome, with complex and inconsistent standards, providing limited benefit to consumers and stakeholders alike. For example, if downstream players pursue traceability in silos, food producers will need to comply with several different types of requirements and the associated costs. This risk is already apparent in the proliferation of voluntary market standards for different foods (e.g., organic food standards, Food standards/certifications for Import/Export) and if horizontal collaboration between retailers is not deliberately designed to be inclusive, it could exclude small-scale producers from markets entirely.

Way Ahead

In the last few years, the Agricultural and Processed Food Products Export Development Authority (APEDA) has been shown growing interest in electronic traceability system for farming products while simultaneously providing guidelines to the farmers about good agricultural practices as well as focusing over the food safety standards for improving better production and distribution. Nowadays, building up traceability system for exports has become easier with help of APEDA Tracenet Module. These steps will go a long way to implement traceability across food supply chains in India.

India has come a long way in the journey of food traceability in the last decade with initiatives from private as well as public sector. There is still a long journey ahead for food traceability India.

Once implemented across supply chains, food traceability will impact our supply chains in the following ways:

- Meet consumer demand for food production transparency

- Enhance the ability to identify, respond to and even prevent food safety issues

- Support supply-chain optimization and reduce food loss

- Validate sourcing claims to support sustainability goals

However, the most important questions today are – which food company will take the lead in implementing traceability in food supply chain? Is the consumer ready to bear the higher cost owing to increased usage of technology in implementing traceability? What will be the role of government regulators in implementing traceability in food supply chain? There are no easy answers to these questions, however, we as a consumer must ask all the stakeholders to implement traceability in food supply chain. No single company will be able to solve the complex issues underpinning traceability agenda alone. Building sustainable value chains in traceability will take a strong commitment and collaboration between public and private players.

For companies at fence evaluating their options, it’s time to act. For those piloting and experimenting, it’s time to scale. And for companies operating full-scale projects, it’s time to scale up the benefits and share the learnings with other industry players. It is also time for Indian food processing sector to be at the forefront of the upcoming food supply chain revolution!