Khadi

An Industry Overview

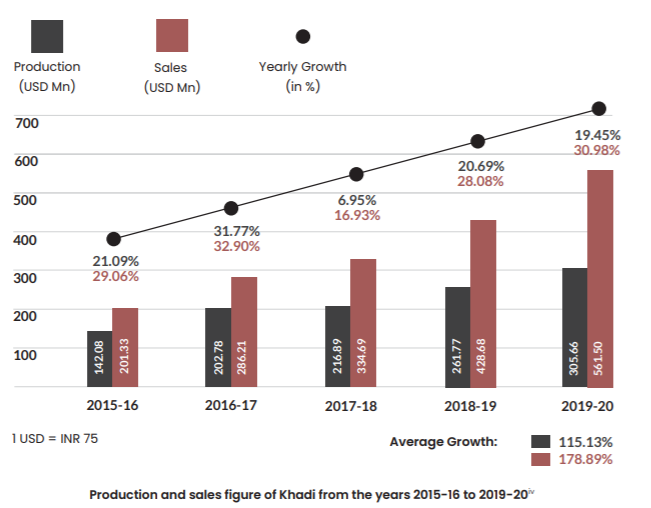

Khadi, a handspun cloth was at the heart of India’s struggle for independence. It has, since, become a symbol of ‘swadeshi’ and freedom. The simple act of adopting khadi, as propagated by Mahatma Gandhi, took the freedom movement to the masses, and made khadi a symbol of pride, heritage, and simplicity. Gandhi firmly believed that khadi could make India self-reliant. In many ways, this resonates with Prime Minister Narendra Modi’s vision for India and the spirit of Aatmanirbhar Bharat(self-reliant India). Khadi’s success is largely attributed to Khadi and Village Industries Commission (KVIC), a statutory body under the administrative control of Ministry of Micro, Small, Medium Enterprises (MSME), Government of India. KVIC was set up in 1954; today, it employs millions of producers with over 7,000 stores and 2,408 khadi institutions across India.i

Khadi has grown unprecedentedly in the past decades. KVIC, too, has registered a turnover of close to INR 90,000 crore ($ 12 Bn) in FY20, up by 16 per cent from FY19.ii KVIC has institutionalised and popularised the use of khadi in India and across the world by incorporating a vast variety of products that include hand or mill spun fabrics, and indigenous honey and herbal soaps. It promotes a rural-based economy and supports artisans by generating employment for over 600,000 workers.iii

Prime Minister Narendra Modi has repeatedly urged people to buy khadi products.

“I keep insisting that we must buy some handloom products made by our weavers, our khadi artisans.”v

- Narendra Modi

Prime Minister of India

Such persistent advocacy from the prime minister has resulted in an exceptional rise in demand for khadi.

Khadi, often referred to as a ‘fabric of freedom’, has undergone many transitions. It has taken on new resonance as a ‘home-grown luxury’ in the context of India’s growing economic power. In more recent times, khadi has emerged as a power to reckon with in India’s fight against Covid-19.

Nitin Gadkari, minister of MSME has highlighted that the MSMEs are the heart of the Indian economy, that contribute 29 per cent of the GDP and have created 110 Mn jobs so far.xxxvii Khadi is an important part of the MSME and is poised for further growth and higher revenues along with an increasing domestic and international market size.

“Setting a target for the khadi and village industries sector to reach a turnover of INR 5 lakh crore ($ 67 Bn) in the next five years from the current level of INR 75,000 crore ($ 10 Bn), this sector can create fifty million new jobs.”xxxviii

“Setting a target for the khadi and village industries sector to reach a turnover of INR 5 lakh crore ($ 67 Bn) in the next five years from the current level of INR 75,000 crore ($ 10 Bn), this sector can create fifty million new jobs.”xxxviii

- Nitin Gadkari

Minister, Ministry of Micro, Small and Medium Enterprises (MSME)

Leveraging Khadi

To fight the Pandemic

Early evidence suggests that Covid-19 could be air-borne, therefore, the US-based Centers for Disease Control and Prevention (CDC), and the World Health Organisation (WHO) recommends greater use of face masks or face covers as a complementary measure to reduce the spread of community transmissions. Face masks or non-medical masks are different from surgical masks and N-95 respirators that are used by health care professionals and frontline workers. Although using N-95 masks would be ideal, other kinds of face masks or face covers have been recommended for the public and could be an affordable option, particularly for the weaker sections of society.

As the caseload of coronavirus grew in India, many people realised the importance of wearing masks as a pre-emptive measure to reduce the threat of community spread. In April 2020, the central government issued an order mandating wear of face masks for all, when stepping out of their homes. Along with the well-accepted measures of physical distancing and frequent hand washing, the use of face masks or face-covering emerged as the third pillar of community action.

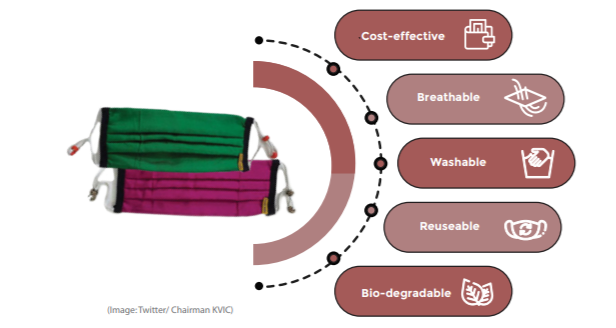

Recognising the sharp increase in demand for masks, several organisations began mass-manufacturing face masks of varying kinds. This presented a unique opportunity for KVIC and several other khadi producers to join forces and meet the rise in demand for face masks. The bio-degradable double-twisted khadi fabric is an ideal choice because it retains 70 per cent of the moisture content that allows air to pass easily, making the masks very comfortable. One meter of khadi fabric produces about ten double-layered masks that are 7 inches in length and 9 inches in breadth, with three pleats and four strips, attached at each corner, used for tying.vii

Khadi Mask

Manufacturing Ecosystem

KVIC’s napkin stitching centre in Nagrotta, near Jammu, was the first to be converted into a mask stitching centre, with production having begun on April 15, 2020. The Nagrotta mask stitching centre produces nearly 10,000 masks every dayviii and provides livelihood to over 300 women belonging to families affected by terrorism in the union territory.

At the same time, the chairman of KVIC issued an appeal to all khadi institutions in the country to donate at least 500 masks to the collectors of their districts for further use and circulation, in a bid to support local administrations across the country. The appeal received an overwhelming response; khadi institutions in almost all states had provided 500 masks to additional district collectors by April.ix

Concerted efforts of various Self-Help Groups (SHGs), Non-Governmental Organisations (NGOs) and khadi institutions across India helped several states to efficiently manage the supply of masks. More than 170,000 masks were produced in Rajasthan, of which 100,000 masks were made available free of cost to district administrations, police personnel and hospital staff. The state has 58 khadi institutions that provide employment to 1,553 workers.x

In another unique initiative, Department of Posts, Jharkhand Circle signed an agreement with Kasturba Gramodyog Sansthan, Ranchi to market khadi masks through various post offices in the state, to ensure masks were available to all. An e-payment software has been introduced to streamline the process further.xii

Women of Patiya and Bamroli villages in the Bodeli taluka of Chhota Udepur, near Vadodara in Gujarat, turned the crisis into an opportunity by earning $ 140,000 within a week of sewing 12,000 masks. The Gujarat state government bought these masks to distribute among health workers and other staff members.xiii

KVIC confirmed that it received orders for nearly 900,000 face masks across the country. These include over 700,000 masks for the Jammu & Kashmir government, over 40,000 masks from various central government ministries, Rashtrapati Bhawan and the Prime Minister’s Office. Orders from the public are received over emails and, on average, 4,000 masks are sold every day from their Delhi stores. More than 750,000 masks have been sold already since 15 April, nearly 76,000 meters of fabric has been used for making these double-layered masks and 600 meters of silk fabric has been used for making triple-layered silk face masks in which two layers are made of cotton.

V.K. Saxena, chairman of KVIC, highlights that the popularity of khadi fabric also falls in line with the prime minister’s message of ‘vocal for local’ in good measure.

“Khadi is our very own fabric. Buying it will contribute to our own country. The khadi fabric is unmatched - no machine can make 500 count fabric which has the intricacies of handspun and handwoven elements. It is environment friendly and is the greenest fabric of all.”xiv

- V.K. Saxena

Chairman, KVIC

Uttar Pradesh

Leading the way in Production of Khadi Masksxv

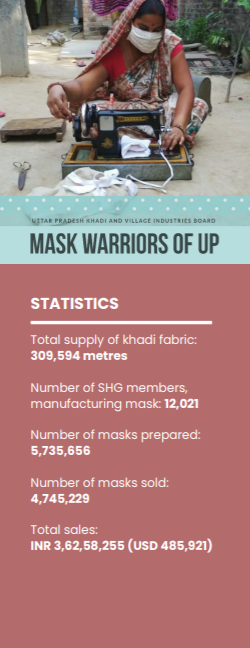

Uttar Pradesh, one of India’s largest states, became the first to decide to use khadi to fight against Covid-19. The Uttar Pradesh government, in an exemplary move, placed an order for 660 Mn khadi masks as early as April 4, 2020. By manufacturing khadi masks through SHGs promoted by the Uttar Pradesh State Rural Livelihood Mission, the state government is ensuring widespread availability of these low-cost masks while generating employment for women in rural areas.

Khadi & Village Industries Board (KVIB) and department of MSME in the state ensured production of khadi masks without having people leave their homes by setting up an implementation plan that caters to all aspects of the supply chain. To decentralize the production process, KVIB set up a standard quality parameter and pricing of masks and provided training to the artisans. In places where cloth cutting facility was not available, KVIB roped in the empanelled society, i.e. Indian Green Khadi to provide fabric to the SHGs.

Through its empanelled societies, KVIB has supplied 600,000 meters of khadi fabric to SHGs, promoted by Uttar Pradesh State Rural Livelihood Mission, to produce 5 Mn khadi masks. The state government has provided a subsidy through its COVID-19 fund to keep the price of each mask at INR 5 to make it affordable for the masses. This initiative, which has provided a source of income to 600,000 women of SHGs who earned around INR 200 a day has been crucial in sustaining livelihoods during the lockdown. So far, close to 5.7 Mn masks have been manufactured and sold by the SHGs in the state, and the process continues.

In conjunction with KVIC’s initiatives across India, several other key players have come forward in this joint effort to leverage khadi to combat COVID-19.

Khadi Kavachxvi

Dharwad, Karnataka

Khadi Kavach, an innovation initiative by a young student, has quickly become a brand name of khadi masks manufactured by AquaKraft Projects Pvt. Ltd., under its sustainability initiative. Produced by one of the oldest khadi societies in India established in 1956 at Dharwad, Khadi Kavach employs over 200 women SHGs. It has been retailing and actively distributing masks to the Mumbai Police, security personnel, the Indian army, and villages across Maharashtra, Karnataka, New Delhi, Roorkee and Haridwar.

“We chose khadi because it is washable, reusable, durable and allows maximum air to permeate making it more comfortable than synthetic masks. We piloted a crowdfunding program, distributed amongst the needy and based on its success we are now retailing to the general public.”

- Chinmayee Kusnur and Nachiket Jamadar

Co-Founders, Khadi Kavach

Ecotattvaxvii

Wardha, Maharashtra

Ecotattva produces 200,000 khadi masks a month and employs 250 women for stitching, 150 for weaving, 150 on the charkha and 10 artisans for dyeing and printing, all from SHGs.

“Ecotattva follows the parameters of quality fixed by KVIC. Our effort is an embodiment of the prime minister’s recent speech exhorting ‘Be Vocal for Local’ which rings the bell to connect such platforms to millions of people pan India.”

- Anagha Balaji

Director, Design & Marketing at Ecotattva

KhaDigixx

Bhopal, Madhya Pradesh

To combat COVID-19, KhaDigi is manufacturing protective face masks which are designed to fit everyone, including children. They come with a built-in pocket, where a replaceable melt-blown filter can be inserted. The filter increases the Bacterial Filtration Efficiency (BFE) of the masks to 99.7 per cent, making them more effective than homemade masks. The design of the masks also makes the disinfection/sterilization process easier.

"At present, we are working with 50 women who are making masks at a centre owned by Mahashakti Seva Kendra in Bhopal. They make around 80 masks a day and earn dignified employment. So far, we have sold 100,000 khadi masks to corporates, banks, and other social institutions.”

- Umang Shridhar

Founder, KhaDigi

Greenwear Fashion Private Limitedxviii

Lucknow & Barabanki, Uttar Pradesh

Greenware employs 485 women and 167 weavers. It manufactures 2,500 khadi masks a day in a centralised production facility and 3,000 masks a day through rural women from SHGs across eight blocks of Lucknow. The three-ply masks are 100 per cent cotton, double-layered with a pocket for filter stripe, and fabric drawstring in accordance with the manual on homemade masks issued by the Office of the Principal Scientific Advisor to the government of India.

Vandana Kumari, a mother of two daughters, lives in Mall Village in Lucknow and with no means of income during the lockdown, was encountering hardship. Greenwear provided her with 100 pieces of fabric with which Vandana stitched masks and earned an income of INR 400 a day. “I was able to send INR 6,000 to my husband who had also lost his job at a factory in Surat and helped him return to our village.” says Vandana. In May, her husband, too, joined the Greenwear workforce.

“Besides the hardships due to lockdown during coronavirus outbreak, the situation has taught us to value the most important aspects of livelihood creation--compassion, creativity and care. Artisans who work from their homes, if supported with appropriate supply chain and skilling, will work wonders in the upcoming model of localised and circular economy. We were able to engage women workforce more than ever during this time due to mask manufacturing.”

- Abhishek Pathak

Director, Greenwear Fashion Private Limited

Khadi Londonxix

London, United Kingdom

Khadi London was co-founded by Kishore Shah and his associate six years ago. Shah’s association with khadi dates back to his volunteering experience in the Sarvodaya movement, a land reform campaign that transformed into a drive for village autonomy and in which khadi played an integral role. Khadi London is one of the few organisations that produces organic cotton masks and caters to demand in the United Kingdom.

The two-layered organic cotton masks are made of ‘desi cotton’, a sustainable crop that is resilient to harsh climate, local pests, requires very little water or pesticides and is referred to as ‘Kala cotton’ by farmers. It is found in the desert region of Kutch in Gujarat.

Khadi London works closely with Gram Sewa Mandal that supports the growth of organic cotton by providing farmers with seeds, along with marketing and training support.

In a conversation with Invest India, Kishore Shah highlighted how the quality of cotton is compromised if it is compressed before it is processed and spun. Since cotton is a porous material, it is recommended that it be processed at the same place it is sourced, to avoid any deterioration in quality.

Reiterating that there is a growing export market for khadi masks, Shah said,

“Although countries like the UK have not made it mandatory to wear face masks, people are voluntarily wearing them especially where it’s hard to keep a necessary distance.”

- Kishore Shah

Co-Founder, Khadi London

Save the Loomxxi

Kerala, India

An NGO founded by Ramesh Menon, in collaboration with Gandhi Smarak Seva Kendram at Nathiatukunnam in Kerala’s Paravoor district, undertook a project to produce khadi masks under the ‘save the loom’ initiative. Witnessing the second wave of cases in March and anticipating demand for masks, the initiative began training women who live around the production centre of Grama Seva Mandram to make masks. As Kerala went into lockdown, material was supplied to women at their homes, many who have been donated with sewing machines to earn a livelihood after the Kerala floods.

Over 110,000 masks were made to serve institutional and individual orders. Presently, the state khadi board has 300,000 masks in stock. The initiative, also through the Samraksha movement (a symbol of protection for wearers and weavers), retails khadi masks through fashion stores in Trivandrum. Masks were donated to Kerala Police, Central Industrial Security Force and Fertilisers and Chemicals Travancore, and have received whole-hearted endorsements from Arif Mohammad Khan, Governor of Kerala, Lokanath Behera, Director General of Police, Kerala and Shashi Tharoor, Member of Parliament and others. Besides single-layered and three-layered masks, the initiative is also exploring new designs with nano and water-repellent fabric.

Reflecting on global demand for masks, Ramesh says,

“Masks are not a fashion accessory but a necessity in safeguarding oneself from Covid-19. Cost-effective and cloth masks will continue to have a demand in the current scenario, not just within the country but outside India as well. Since production costs are lower compared to other parts of the world, if its rightly made, with social benefits, it could cater to the need globally as well.”

- Ramesh Menon

Founder, Save the Loom

Towards a Sustainable Solution

Khadi can truly enable India to be a front-runner in achieving its Sustainable Development Goals (SDGs), especially since sustainable fashion has become increasingly mainstream and essential to consumers across the world.

“Khadi mask manufacturing fulfils 8 of the 17 United Nations SDGs across health and well-being, saving water, women empowerment, climate action, zero carbon footprint, responsible production and consumption, innovation and industry, collaborations and partnerships.”

- Dr. Subramanya Kusnur

Founder, AquaKraft Group

The spinning of khadi on the charka uses no machines or energy, making it a zero-carbon footprint and eco-friendly fabric. A metre of khadi fabric consumes only three litres of water in comparison to one metre of mill-produced fabric that requires 55 litres of water. xxii

Mass production of masks at homes with the help of SHGs have provided a livelihood for rural women in these times of hardship. India’s SHG movement has evolved from small savings and credit groups that sought to empower poor rural women, into one of the world’s largest institutional platforms for the poor. More than 19 Mn masks have been produced, till date, by around 20,000 SHGs across 27 Indian states. Today, 67 Mn Indian women are members of 6 Mn SHGs and they too have come to the fore as foot soldiers in India's fight against the virus.xxiii

According to Abhishek Pathak, the director of Greenware, khadi has only 1 per cent market share in the Indian domestic textile market and can increase to 5 per cent with interventions like solar charkha. xxiv The use of solar energy powered charkhas can make khadi more competitive by reducing the cost of yarn, decentralising production and generating jobs in the rural sector. Gandhi’s vision of decentralised, democratic and diverse systems of production in village clusters can be achieved with innovations in spinning, weaving and related technologies that can help khadi survive and evolve over the decades.

According to studies conducted by the Ministry of MSME, solar charkhas have boosted khadi fabric production 20 times. The khadi vision document states that solar charkhas have also led to more than four-fold appreciation in the income of artisans.xxv

Vocal for Local connecting to Global

Export Dimension

Wearing face masks has become the new norm across the world, providing an even bigger opportunity to the industry in the exports market. The sale of disposable face masks have skyrocketed in the past few months. The global disposable face mask market is projected to witness an 8.5 per cent Compound Annual Growth Rate (CAGR) and reach the value of $ 3 billion (Bn) by the end of 2030.xxvi

Chairman of KVIC believes that khadi masks are an appropriate example of ‘Local to Global’.

“The popularity of khadi fabric and other khadi products have grown significantly across the globe in recent years after the prime minister’s appeal. The export of khadi masks will lead to a spike in production and ultimately create large scale employment opportunity for artisans in India.”xxvii

- V.K. Saxena

Chairman, KVIC

The growth in the global fashion mask industry is creating ripples in India’s mask manufacturing market, which has been estimated at INR 10,000 crore -12,000 crore ($ 1.3 Bn - 1.5 Bn).xxviii Going forward khadi masks are also now set to go global. KVIC is exploring the possibility of exporting khadi cotton and silk face masks to foreign countries after the Ministry of Commerce and Industries lifted the ban on export of non-medical/ non-surgical masks of all types. The masks will be supplied to countries like the US, Dubai, Mauritius and several European and Middle Eastern countries where khadi’s popularity has grown significantly over the last few years. KVIC plans to sell khadi masks in these countries through Indian embassies and missions abroad.xxix

Kishore Shah, Co-founder of Khadi London, foresees a higher demand for organic cotton masks in western countries.

“Khadi's soft power potential for India remains largely untapped. Very few people in the UK have any knowledge of khadi. Organic khadi masks have given us a unique opportunity to make khadi better known. The story-telling behind the mask also brings a unique traceability aspect to their product for the ethical consumer market.”xxx

- Kishore Shah

Co-founder, Khadi London

Moving forward, Khadi London intends to extend its range to non-organic products and tap into wholesale demand and establish scale by collaborating with both private and public enterprises in India. xxxi

The textile industry in India is gearing up to make a variety of masks as people are increasingly becoming safety-conscious and can be seen wearing face masks as they step outside their homes. Prabhu Damodaran, convenor of Indian Texpreneurs Federation (ITF) has estimated that India’s export revenue from masks alone would be between INR 2,000 crore and 3,000 crore ($ 262.5 Mn – $ 393.7 Mn) within this year.xxxii Hence, khadi masks, that are cost effective, breathable, washable, reusable and bio-degradable, are sure to find a large demand and carve a niche for themselves in this growing export market.

The Khadi Way

Pioneering the Future

Face masks have become ubiquitous worldwide following the outbreak of the coronavirus, creating a business opportunity for this sustainable fabric. Khadi has stood the test of time and has re-entered our lives when the country was facing an acute shortage of masks and other critical equipment like ventilators and personal protective equipment. Rooting for a revival in a skill that only India possesses, and a highly differentiated product that no other textile ecology in the world possesses, khadi is the way forward.

Integrating fashion

Khadi can be re-positioned to the young aspiring India, without having to lose its identity. New woven designs and colours for masks can be made appealing to the younger audience especially millennials who can be the flag bearers for this unique fabric. Besides traditional fairs and e-commerce websites, promoters should leverage social media platforms and influencers to highlight the diversity and make khadi a fashion statement.

Diversification in the current product line

Diversification in the current product line

The khadi industry must leverage the increased production of sanitisers, liquid soaps and other such products, and undertake production of a diverse range of products, by collaborating with premier technical and design institutes. For instance, KVIC has developed a new line of khadi face masks of camouflage prints for the defence forces, to match their uniforms.

Transition to medical masks

Transition to medical masks

According to the WHO, demand for masks has multiplied 100 times since the outbreak of the pandemic.xxxiii The need for ‘filtration media’ that makes face masks effective has increased dramatically because it is used in medical face masks and N95 masks. The US Department of Health and Human Services anticipate a demand for 3.5 Bn face masks for health workers across the globe.xxxiv Integrating an extra layer of non-woven melt-blown fabric to improve functionality will be a significant step to making khadi masks more effective.

Institutional demand

As an extension of promoting Make in India products and khadi, KVIC is already in discussion with central forces to supply raw material for over one million uniforms for the para-military forces.xxxv A similar proposal may be initiated by state governments, in collaboration with KVIC, to meet the demand for masks and uniforms for school children in government schools and institutions. This will be a good measure to ensure the safety and comfort of children when schools re-open.

Initiating Dialogue

about Khadi

A two-day international conference, organised by Confederation of Indian Industry (CII), was held in Jaipur on January 2, 2020. It was attended by Ashok Gehlot, the chief minister of Rajasthan and khadi experts from 16 states and other global representatives. To augment the growth of khadi, the state announced a 50 per cent discount on khadi garments, in addition to increasing the revolving fund from INR 3 crore ($ 400,414) to INR 10 crore ($ 1.3 Mn) to support businesses.xxxvi Such platforms are key to initiating dialogues and building genuine collaborations that promote ethical business. Khadi can play a key role in bringing change, not only in fashion but also in how a rural economy can be organised and self-sufficient. Issues such as scale of production, fair wages and promotion of khadi via storytelling from seed to shelf should be principal points of such dialogues and campaigns.

“I feel proud to recall my appeal to the countrymen to buy khadi. I had also appealed to support country's handloom workers. In a very short period, the demand and sale of Khadi and handloom have created a record. You have also made Khadi a big brand. It was a small step, but the results have been outstanding.”

- Narendra Modi

Prime Minister of India

- https://www.kviconline.gov.in/index.jsp

- https://economictimes.indiatimes.com/markets/stocks/earnings/kvics-fy20-turnover-inches-close r-to-rs-90000-crore/articleshow/75628028.cms?from=mdr

- https://www.kviconline.gov.in/pmegp/pmegpweb/docs/pdf/PMEGPscheme.pdf

- https://pib.gov.in/PressReleasePage.aspx?PRID=1613631

- https://www.deccanherald.com/national/north-and-central/rajasthan-making-khadi-masks-amid-covid-19-crisis-837932.html

- https://timesofindia.indiatimes.com/city/hubballi/khadi-masks-a-green-option-to-stay-safe/articleshow/75093084.cms

- https://www.dailypioneer.com/2020/state-editions/postal-dept-inks-mou-with-kgs-to-market-khadi-masks.html

- https://timesofindia.indiatimes.com/city/vadodara/khadi-masks-help-these-village-seamstresses-sew-a-success-story/articleshow/75209729.cms

- https://www.indiatoday.in/mail-today/story/khadi-aims-to-be-most-eco-friendly-fabric-304962-2016-01-22

- https://www.worldbank.org/en/news/feature/2020/04/11/women-self-help-groups-combat-covid19-coronavirus-pandemic-india

- https://www.businesstoday.in/current/economy-politics/narendra-modi-government-s-khadi-initiative-to-create-80-lakh-jobs-in-2016-17/story/228429.html

- https://pib.gov.in/PressReleseDetailm.aspx?PRID=1625755

- https://www.thehindubusinessline.com/economy/indias-textile-industry-is-crafting-a-future-in-global-fashion-mask-market/article31663186.ece

- https://pib.gov.in/PressReleaseIframePage.aspx?PRID=1625755

- https://www-thehindubusinessline-com.cdn.ampproject.org/c/s/www.thehindubusinessline.com/economy/indias-textile-industry-is-crafting-a-future-in-globalfashion-mask-market/article31663186.ece/amp/

- https://www.ndtv.com/world-news/severe-disruption-as-demand-for-masks-soars-100-fold-amid-coronavirus-outbreak-world-health-organiza-2176927

- https://www.cnbc.com/2020/03/30/3m-scrambles-to-meet-coronavirus-demand-for-face-masks.html

- https://economictimes.indiatimes.com/news/defence/over-1-million-paramilitary-men-to-don-khadi-uniform-combat-outfit/articleshow/72376454.cms?from= mdr

- https://thenewsstrike.com/international-conference-on-globalization-of-khadi-khadi-eradicates-differences-between-rich-and-poor-chief-minister/

- https://www.business-standard.com/article/pti-stories/govt-to-soon-change-definition-of-msmes-gadkari-119102200768_1.html

- https://www.financialexpress.com/economy/khadi-aims-high-nitin-gadkari-sets-rs-5-lakh-crore-turnover-target-for-khadi-sector/1818392/

- http://www.kvic.gov.in/kvicres/index.php

- https://www.kviconline.gov.in/msc/

- https://www.frontiersin.org/articles/10.3389/fevo.2021.639216/full